The Ideal Seedbed Preparation Tool

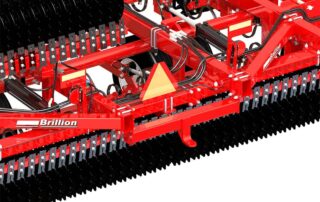

The Brillion Pulvi-Mulcher is a one pass secondary tillage tool designed to finish and firm the seedbed prior to planting. The front pulverizer roller breaks down soil clods and lumps. The cultivator teeth in the middle bring moist soil into the growth zone. The rear pulverizer roller levels and firms the seedbed. Over the years, these machines have been labeled with many names: Pulvi-Mulcher, Roller Harrow, Culti-Mulcher, and Roller Mulcher to name a few. The name doesn’t matter…the concept is the same!

Industry Leader

Long ago Brillion accepted the challenge of providing clod-free seedbeds by developing the Pulvi-Mulcher, a one pass secondary tillage tool. Those pioneering efforts produced a machine with a combination of roller wheels and spring teeth to crush, harrow and condition the soil to provide ideal planting environments for producing bigger yields.

Market Domination

Over the years, Brillion has dominated this market. Heavy-duty pulverizer roller assemblies that can handle the challenges of secondary tillage set the stage. Strong, yet flexible frame members allow the Pulvi-Mulcher to follow the contour of the soil for consistent performance. A selection of pulverizer wheel types and cultivator teeth satisfies the needs of different soil types and conditions. This combination adds up to the industry-leading Brillion Pulvi-Mulcher that meets the challenge of the soil and competition.

The Heavy-Weight in Pulvi-Mulchers

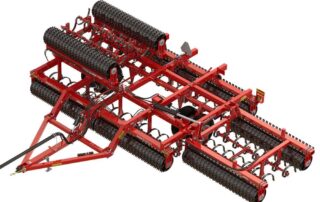

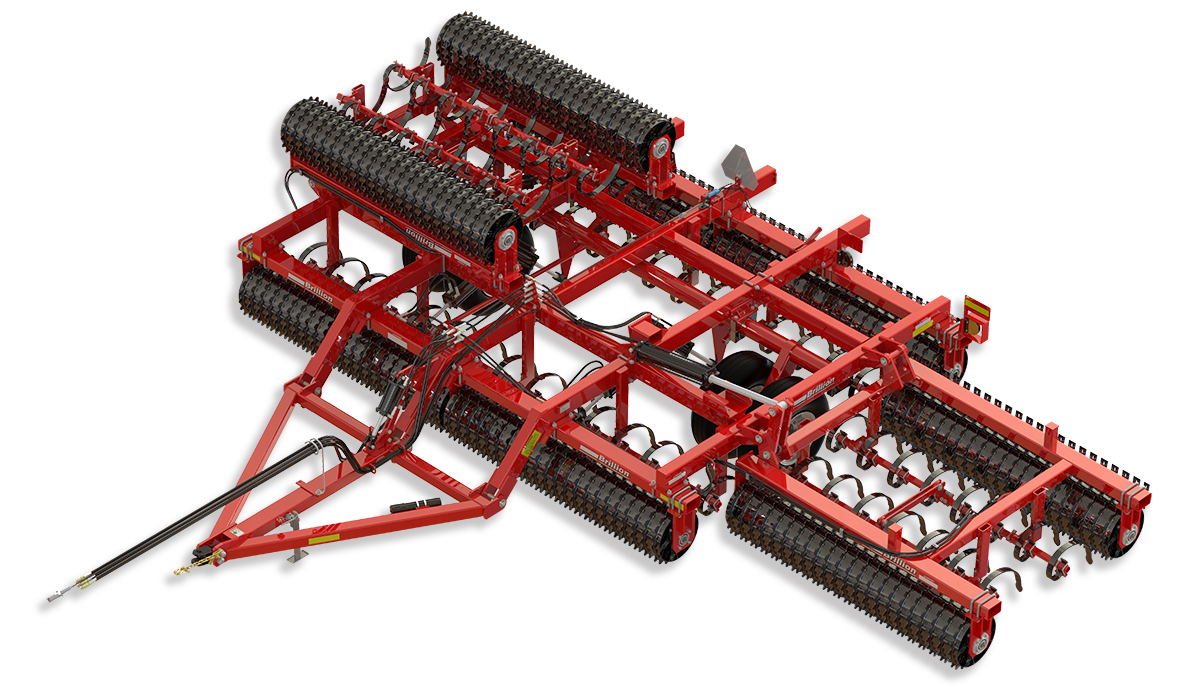

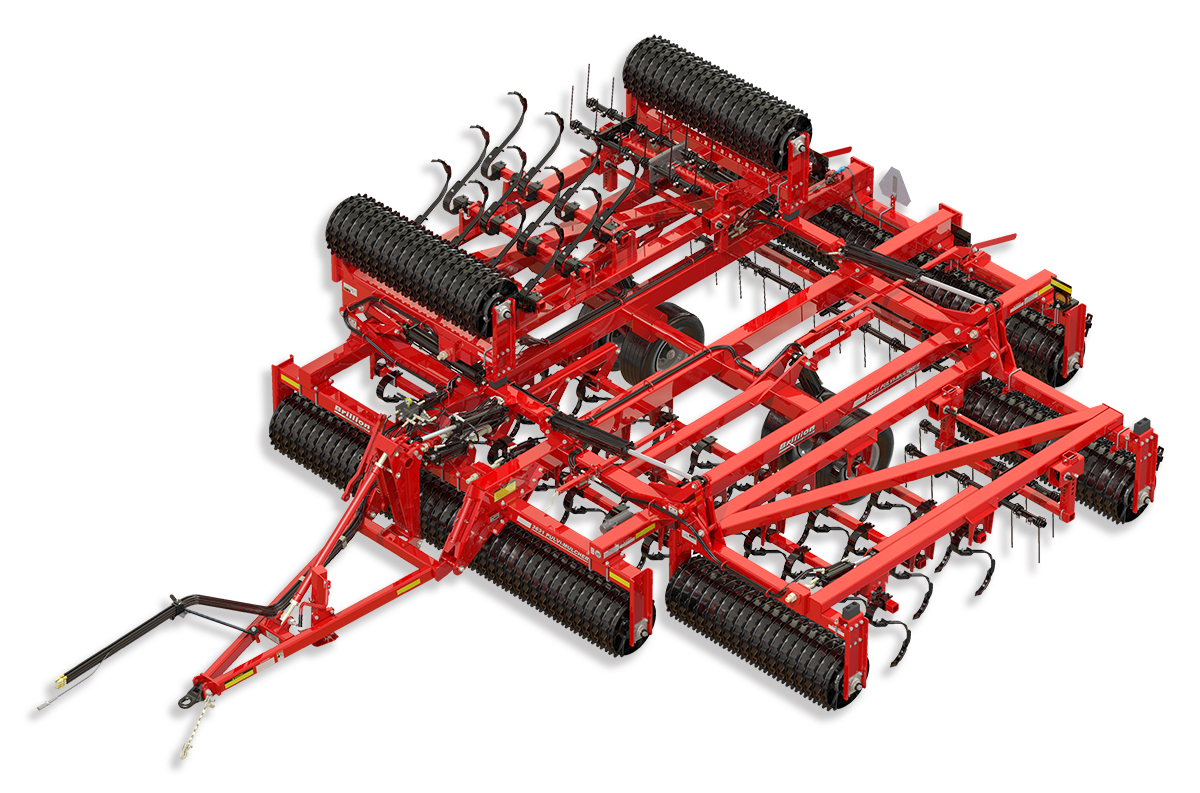

The 3600 Series Pulvi-Mulcher, the latest addition to the model line-up, features wider working widths, increased trash clearance and reduced downtime in the field. The series is available in 21′, 25′, 30′ and 36′ working widths. The 30′ model weights 80% more than the popular WL360 model for more clod crushing power. The 36′ unit is the widest Pulvi-Mulcher ever offered by Brillion.

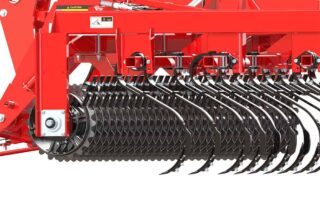

All 3600 Series models feature 8″ roller axles with heavy-duty bearings that improve reliability and reduce maintenance interruptions in the field. The design includes 3 rows of 2-piece edge bent s-tines on overall 6″ spacing. 23″ of under frame clearance improves trash flow through the machine. A coil tine harrow in front of the rear roller helps level ridges left by the shanks. The 3600 Series also features the largest pulverizer wheels ever used by Brillion; all models in this series are equipped with 24″ notched ductile iron wheels.

Sized for Any Size Operation

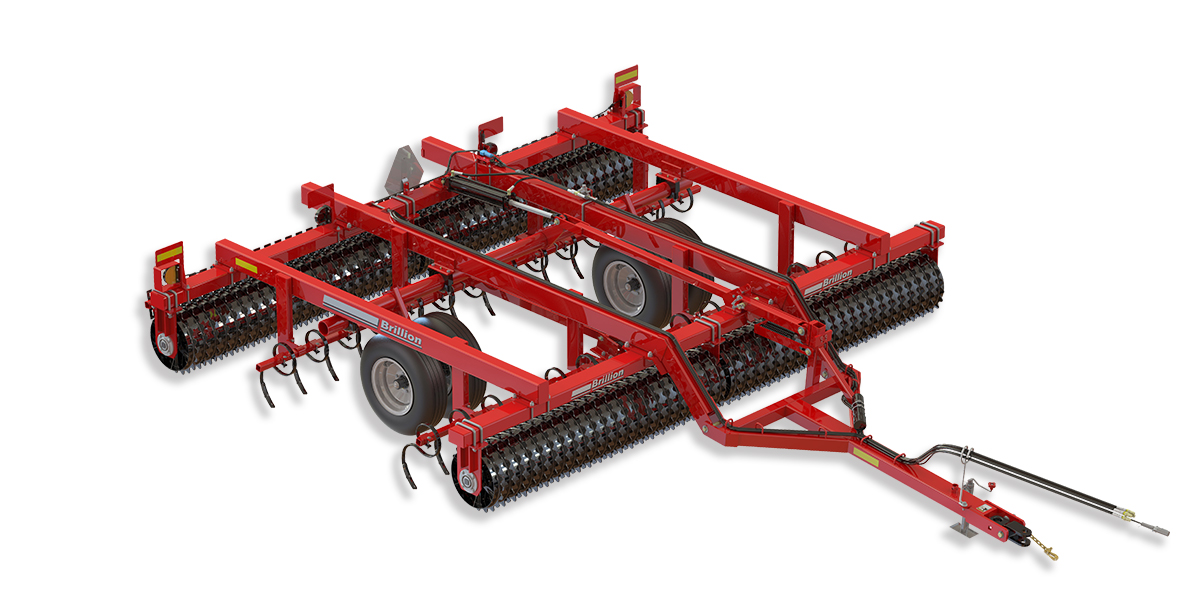

Besides the 3600 Series heavy-weights, Brillion also offers the WL Series with models available in sizes from 21’8″ to 30′. These models feature 4″ roller axles, a choice of 20″ notched or crowfoot ductile iron wheels and two rows of either conventional “C” teeth or S-Tines. The WL Series is flat folding for a narrow transport width and manageable height.

The ML Series revolutionized the industry when it was first introduced. Easier pulling 20″ ductile iron rollers and a high clearance frame brought new life to the Pulvi-Mulcher and is still very popular today. The long frame members allow more room for residue to flow through the machine. The ML Series is available in sizes from 12’6″ to 18’9″ and fits the needs of mid-sized operations by offering all the features of a full-featured machine without the investment of the larger wing fold models.

No matter the size of your operation or available horsepower, there’s a Brillion Pulvi-Mulcher sized perfectly for your needs and for creating your perfect seedbed!

Features

3631 Series

- Three-Section Folding Models in 25′, 30′ and 36′ Working Widths

- Designed for Improved Residue Flow Through the Machine

- Three Rows of Shanks on Overall 6″ Spacing

- Two-Piece Edge Bent S-Tine Shanks for Better Leveling

- 23″ Under Frame Clearance

- 18″ Between Shanks, Minimum of 24″ Between Rows

- 2″ Reversible Points

- Maximum Shank Operating Depth of 5″

- Two-Row Coil Tine Harrow in Front of Rear Roller

- 8″ Roller Axles

- 61 mm Heavy-Duty Bearings

- 24″ Notched Ductile Iron Wheels

- Rear Scrapers Standard on Notched Rollers

- Transport Hitch Floats 25 Degrees Up and 17 Degrees Down

- Wings Float 6 Degrees Down

- Single Point Depth Control

- Wing Hydraulic Down Pressure

- Dual Transport Wheels

- (4) 380/55R16.5 Tires on 25′ Model

- (4) 480/45R17 Tires on 30′ and 36′ Model

- Cat. III, IV or V Hitch

- Transport Height: 9’6″ for 25′ and 30′ Model, 13’8″ for 36′ Model

- Transport Width: 14’8″ for 25′, 17′ for 30′ Model, 18’10” for 36′ Model

- Options Include Front Roller Scraper Kit, Land Leveler, V-Leveler, Coil Tine Harrow Attachment and Rear Hitch Kit

- LED Warning Lights and SMV Emblem are Standard Equipment

- Powder Coat Paint

3620 Series

- Two-Section Folding Model in 21′ Working Width

- Designed for Improved Residue Flow Through the Machine

- Three Rows of Shanks on Overall 6″ Spacing

- Two-Piece Edge Bent S-Tine Shanks for Better Leveling

- 25″ Under Frame Clearance

- 18″ Between Shanks, Minimum of 24″ Between Rows

- 2″ Reversible Points

- Maximum Shank Operating Depth of 5″

- Two-Row Coil Tine Harrow in Front of Rear Roller

- 8″ Roller Axles

- 61 mm Heavy-Duty Bearings

- 24″ Notched Ductile Iron Wheels

- Rear Scrapers Standard on Notched Rollers

- Hitch Floats 15 Degrees Up and 25 Degrees Down

- Wings Float 5 Degrees Down

- Hydraulic Down Pressure for Even Machine Weight Distribution Across the Width of Machine

- Independent Hydraulic Tooth Depth Control

- Dual Transport Wheels

- (4) 12.5L x FI Tires

- Cat. II, III or IV Hitch (Cat. V Optional)

- Transport Height: 13’4″

- Transport Width: 12’3″

- Options Include Front Roller Scraper Kit, V-Leveler and Rear Hitch Kit

- LED Warning Lights and SMV Emblem are Standard Equipment

- Powder Coat Paint

WL Series

- Flat Folding Models in Sizes from 21’8″ to 30′

- Choice of 20″ Notched Ductile Iron or 20″ Crowfoot Ductile Iron Pulverizer Wheels on Front Axle

- Choice of 20″ Notched Ductile Iron or 20″ Crowfoot Ductile Iron Pulverizer Wheels on Rear Axle

- 4″ Roller Axles with Sealed Bearings

- External Bearing Mount Allows for Easy Service

- Fully Adjustable Reversible Scrapers are Standard on Rear Rollers Equipped with Notched Wheels

- Choice of Conventional “C” Teeth or S-Tine Teeth

- Teeth Spaced at 6″

- Maximum Depth of Operation of 6″

- Flip-Flop Style Hitch

- Extra Long Hitch Accommodates Dual Wheel Tractors

- Hitch Point at Center Height of Front Roller Axle

- Coil Spring Counter Balance on 21’8″ and 25′ Models Provides Smooth, Jolt-Free Operation

- Integral Hydraulic Counter Balance on 30′ Models

- Mechanical Transport Lock

- Frame Members Made of 4″ x 6″ Structural Steel Tubing Provide Structural Integrity & Reliability

- Heavy-Duty Transport Rockshaft with Dual Wheels

- (4) 11L x 15-12 Ply Tires on 21’8″ and 25′ Models

- (4) 12.5L x 16-14 Ply Tires on 30′ Models

- Independent Hydraulic Tooth Control is Standard Equipment

- Options Include Front Roller Scraper Kit for Notched Wheels, V-Leveler, Land Leveler and Rear Hitch Kit

- LED Warning Lights and SMV Emblem are Standard Equipment

- Powder Coat Paint

ML Series

- Rigid, Non-Folding Models in Sizes from 12’6″ to 18’9″

- Choice of 20″ Notched Ductile Iron or 20″ Crowfoot Ductile Iron Pulverizer Wheels on Front Axle

- Choice of 20″ Notched Ductile Iron or 20″ Crowfoot Ductile Iron Pulverizer Wheels on Rear Axle

- 4″ Roller Axles with Sealed Bearings

- External Bearing Mount Allows for Easy Service

- Fully Adjustable Reversible Scrapers are Standard on Rear Rollers Equipped with Notched Wheels

- Choice of Conventional “C” Teeth or S-Tine Teeth

- Teeth Spaced at 6″

- Maximum Depth of Operation of 6″

- Flip-Flop Style Hitch

- Long Hitch Accommodates Dual Wheel Tractors

- Hitch Point at Center Height of Front Roller Axle

- Spring Loaded Counter Balance Provides Positive Machine Control

- Mechanical Transport Lock

- Frame Members Made of 4″ x 6″ Structural Steel Tubing Provide Structural Integrity & Reliability

- Heavy-Duty Transport Rockshaft with Dual Wheels

- (4) 9.5L x 15-8 Ply Tires

- Independent Hydraulic Tooth Control is Standard Equipment

- Options Include Front Roller Scraper Kit for Notched Wheels, V-Leveler, Land Leveler and Rear Hitch Kit

- LED Warning Lights and SMV Emblem are Standard Equipment

- Powder Coat Paint